Porcelain Insulator News

by Elton Gish

Reprinted from "Crown Jewels of the Wire", July 1999, page 16

We have a mixed bag to share with you this month. Two are unusual pin-type

insulators and the rest are non-pin-type insulators you don't often see.

Hopefully, many of you have never seen them and will now become more informed.

You probably know by now that there is seemingly an endless variety of porcelain

insulators most of which are not necessarily pin-type insulators. We really

haven't shown very many in this category. But first, let's proceed to more

mundane pintype offerings.

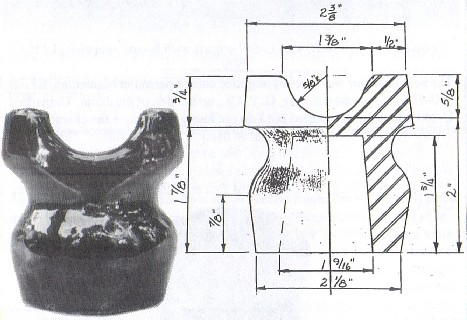

Earlier this year, Harry Winegarden found two interesting insulators in an

antique shop in Nelson, British Columbia (southeastern BC). Both were unmarked U-518. One of the U-518's was poorly trimmed and it looks a bit lopsided from

one side. He went back to the store and the owner found a third one. Harry

commented that the town of Nelson might have used U-518's in their own

distribution system since the store had three of this unusual style.

U-518 was

made by the Lima Insulator Co. (1904-1908) and is a variation of U-519. The

photograph shows both insulators and you can easily see the difference between

the two styles. Note that U-519 is thicker, stronger, and has a larger cable

groove. Only one unmarked U-519 has been reported and only one marked U-519 is

known. The marked one has the incuse marking, "LIMA, N.Y.", in the

bottom of the cable groove. Both insulators have the characteristic deep cable

groove dimple that cuts down about 2/3 of the way across the wide tie-wire

groove. This unique feature is not found on any other insulator that I am aware

of. Both insulators have glazes that are characteristic of Lima insulators, a

dime-sized impression at the top of the fully glazed pinhole, and parallel bands

in the tie-wire groove left by the trimmer blade. A few other unmarked U-518's

were reported in the survey for my book, Value Guide for Unipart and Multipart

Porcelain Insulators; however, these may be the more modern version made by

Victor Insulators Inc. (1935-1955). One U-518 was reported with the marking from

that company.

Unmarked U-518 (left) and U-519 (right) with incuse marking, LIMA, N.Y.

The

next insulator was recently acquired from a person in Manhattan, KS. It is U-358

with incuse marking, G. P. Co., on the side of the dome. Unmarked U-358's have

been reported but I do not know if any have the characteristic speckled

reddish-brown glaze found on many G. P. Co. insulators. This marked U-358 has an

extremely shiny glaze that adds to its appeal. For those of you not familiar

with this marking, it was used by General Porcelain Co. (1923-1927) in

Parkersburg, WV. This is the ftrst reporting of the G. P. Co. making U-358.

U-358 with incuse marking, G. P. Co.

Now let's move on to some interesting non-pin-type insulators. Larry Harmon

first reported this one in the October 1972 issue of Crown Jewels of the Wire

and again in Jack Tod's PIN column in November 1972 on page 16. Larry sent Jack

a nice drawing that is reproduced here. The fully glazed "pinhole" is

smooth but not what we call "threadless". That term is reserved for

insulators made before the invention of the threaded pinhole and typically

manufactured from the 1850's to possibly as late as the early 1870's. The

insulator is crudely made with carving marks all around just below the tiewire

groove. It appears to have been made circa 1910's or 1920's. I would guess that

it was some sort of "equipment insulator" made for a specific

electrical device. The weight of the conductor probably held the insulator on a

knob or short smooth pin. The upward taper of the pinhole and smooth glazed

surface would not be suitable for cementing.

Small unusual porcelain insulator has a smooth pinhole

and dark brown glaze.

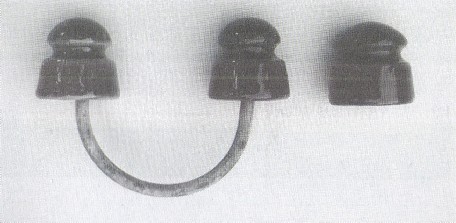

I'm not sure if this next insulator has been reported before. Keith Roloson

(NIA #3201) recently asked me about it. He said he has never seen one in all his

years of collecting. I have seen this little dark blue insulator 2-3 times and

the ones shown in the photographs are from my collection. Note that two of the

little insulators (1-1/2" x 1-1/2") are cemented onto the ends of a

metal "U" bracket. Keith has one like this, too, and I have seen at least one other

"U" bolt arrangement and perhaps a couple of individual insulators. I

cannot imagine how the "U" bracket was mounted. It would have required

a special clamping attachment in order to hold the insulators upright. Note the

third separate insulator in the photograph. It is slightly different than the

others. The second photograph shows the details of the unglazed squared-off

pinhole. This allowed good adhesion by the cement. I assume the ends of the

"U" bracket are not smooth but shaped in some way to aid in cement

attachment. The glaze is thin on the wire groove and skirt edges making it

lighter blue. The little insulators are made of dry process porcelain.

Miniature-size dark blue, porcelain insulators

cemented to a metal

"U" bolt.

This view shows

the pinhole detail

of the little insulators.

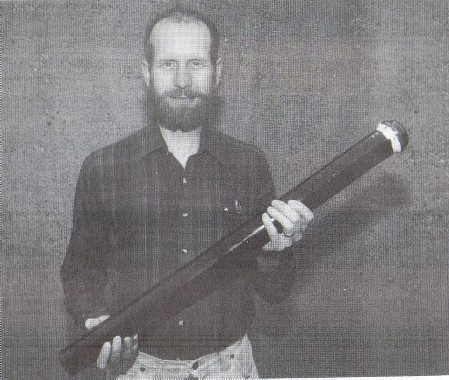

Rick Bentley recently showed me a very large wall tube in his collection. It

is about 34" long and 2-1/2" in diameter with a dark brown glaze! The

white under the enlarged end is the unglazed firing rest, which probably means

the tubes were hung on hangers during the firing process. The center of the tube

is fully glazed and was crudely drilled out when the clay was still pliable. On

close inspection we found the incuse marking, THOMAS, close to the smaller end

and nearly obliterated by the dark glaze. From the glaze color, I would guess

that the tube was made in the 1910's or 1920's. This is the longest wall tube

that I have seen and it is very uncommon to find wall tubes that have been

glazed, too. Wall tubes of this size were used in power plants and substations

to safely bring the large conductors through a wall and up to the power line.

Usually they were cemented in a brick or concrete wall. The glaze on Rick's tube

shows about a 6" length in the center of the tube where the glaze surface

is slightly etched. This indicates it was cemented in a wall of about that

thickness and the alkaline cement dulled the glaze surface. You can imagine the

difficulty in extracting a large tube from a concrete wall (usually up near the

top of the wall) without breaking it. Rick's wall tube is a rare find indeed.

Rick Bentley with his long porcelain wall tube made by Thomas.

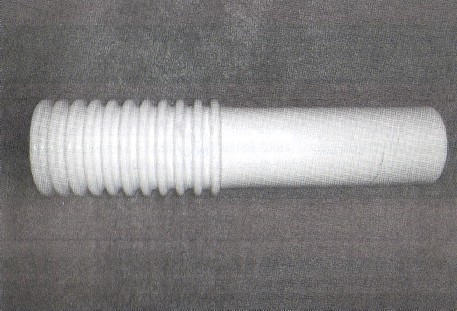

Mike Spadafora found a very old wall tube in 1997 in a dump behind the Flint

Creek Powerhouse near Anaconda, MT. The outside surface is nice an shiny and

doesn't appear to have been used; however, you can see marks inside the tube

left by the large conductor cable. The wall tube is fully glazed inside and out

with a transparent glaze and it has an unglazed firing surface on the smaller

end. The tube is somewhat crudely made. There is an incuse manufacturing date, 1

29 06, near the smaller end. The tube is 24-1/4" long, 5" diameter on

the small end, 6" diameter on the larger end, and the inner hole is 3-1/4" in diameter.

Large white glazed wall tube made in 1906.

Perhaps in the next issue of PIN we will discuss very small wall tubes that

are glazed. Some are glazed white, brown, or a pale greenish color. Most small

wall tubes for house wiring are unglazed white porcelain. The glazed tubes are

older and more difficult to find. You will be surprised at the variety. I'm

looking for glazed wall tubes so please let me know if you have any of these

unusual insulators.

|